Requirements:

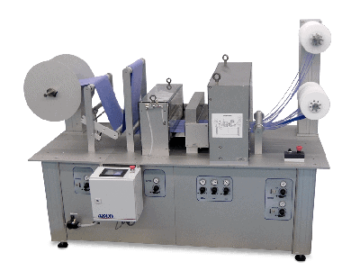

This application required unwinding and precisely cutting pieces of coated material in roll form.

Material: 20” wide roll of fire stopping material with applied liner.

Our Solution:

AZCO Corp. designed and manufactured a custom Cut-to-Length assembly with a slitter station, dancer unwind and roll feeder.

The roll of material is loaded onto a dancer unwind.

The operator will then load of release liner onto the sheet of material.

The material travels under a dancer assembly and into the roll feeder.

Liner is pressed onto the material.

A no product sensor automatically shuts down the unit when no product is sensed entering the rollers.

The roll feeder assists in feeding the material into the Crush Cut slitter station.

Slitter blades are pneumatically raised and lowered with a flow control to allow for plunge cutting.

Slit material then travels out of the slitter station and into the cut to length station.

The cut-to-length station cuts the product into precise pieces.

A jam sensor automatically shuts down the unit when no product is sensed exiting the knife assembly.

All components are mounted to a common aluminum baseplate and frame.

Learn More

Requirements:

This application required unwinding, slitting and cutting to length plastic film from a roll.

Material: Plastic film in roll form

Learn More

Requirements:

This application required punching 4 holes into plastic cards and then cutting the cards in half lengthwise.

Material: 85mm x 54mm x .75mm laminated plastic cards

Learn More

Requirements:

This application required reducing a high performance material from roll form into .5” x 1” pieces.

Material: Roll of high performance material

Material Width: 12”

Slit Width: .5”

Cut Length: 1”

Learn More

Requirements:

This application required slitting a multi-layered product to the following specifications:

3” long

18” wide

2” or 4” slits

Material: Multi-layered product

Learn More

Requirements:

This application required slitting material in sheet form and then rewinding the slit material.

Material: Rubberized caulk

Material Width: 14”

Material Thickness: 4mm

Slit Width: ½”

Learn More

Requirements:

This application required unwinding material from a roll, slitting and trimming the material, and removing and rewinding top and bottom release liners.

Material: 20” wide 3 Ply Film.

Learn More

Requirements :

This application required unwinding material from a roll and cutting it to length, ensuring that the material remained flat and curled.

Material : 4″ wide woven product.

Learn More

Requirements:

Unwind, slit, cut to length, and rewind material from roll.

Material: Varying widths 3/8” – 12 ¾ “ tape

Learn More

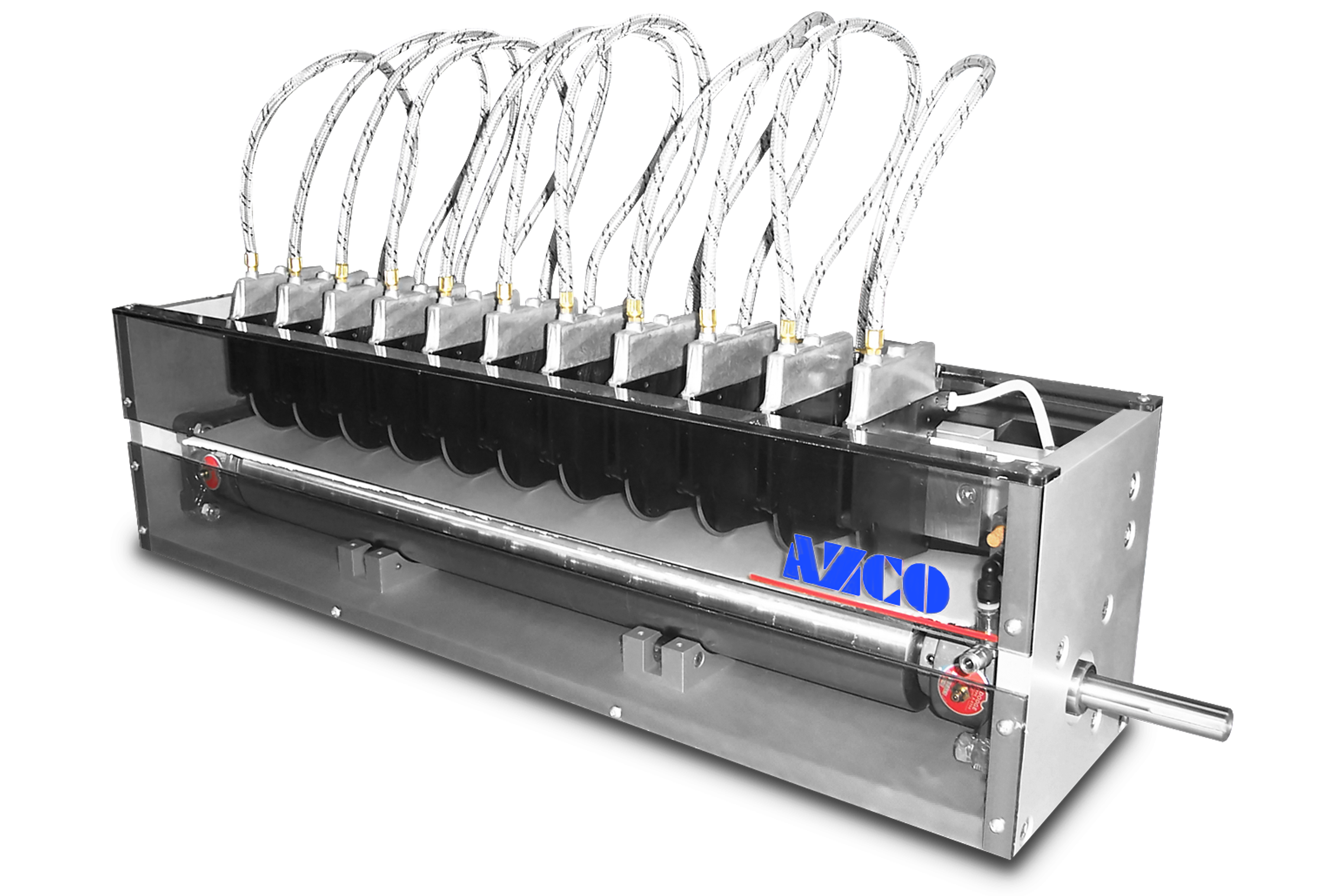

The AZCO ACU-SLIT™ slitter module can operate as an in-line option on the cut-to-length assemblies, a replacement for worn slitter stations on any web machine, or an add-on to any web processing equipment.

The simplest application of a slitter is where it is placed immediately before a roll feeder. As the feeder pulls the web, it is automatically slit to size.

Crush cut slitters effectively cut thicker, low density materials such as filter media and nonwovens. It is also a convenient unit for frequent changeovers.

Learn More