BLOG POSTS

SUR-SIZE™ Sheeters: Advanced Cutting Technology for Precision Material Processing

SUR-SIZE™ Sheeters: Advanced Cutting Technology for Precision Material Processing In today’s fast-paced manufacturing world, efficiency and precision are

Rotary Die Module: Increase Production and Accuracy While Reducing Costs

Rotary Die Module: Increase Production and Accuracy While Reducing Costs A rotary die station is a critical component

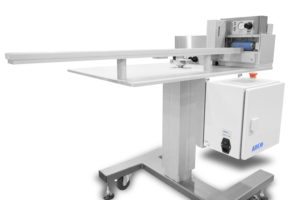

Your Solution for Precise, Accurate and Reliable Cuts For Flexible Materials

Looking to improve your production processes and achieve consistent results? We designed the SUR-SIZE™ FG series cut-to-length modules with you in mind. These systems are compact and easy to use — just bolt one in and start using it.

ValvPak® Valve Applicator Machine Advances Sustainability in Food Packaging

One of our latest machines has arrived just in time for PACK EXPO 2024. This valve applicator applies

Innovative Strategies To Avoid Adhesive Buildup in Cutting Applications

When it comes to cutting adhesive materials, it’s challenging to offset the buildup of adhesives on the blades. This buildup can degrade cut quality, while frequently cleaning and replacing the blades drive cost, resources and downtime.

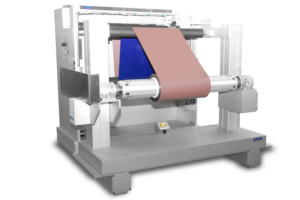

Exploring Our SUR SIZE™ Sheeter FGW 1650 for Unwinding, Slitting and Cutting

Exploring Our SUR SIZE™ Sheeter FGW 1650 for Unwinding, Slitting and Cutting We’re spotlighting our SUR SIZE™ Sheeter

Electric Knife Option Elevates Sheeter Performance and Versatility

Electric Knife Option Elevates Sheeter Performance and Versatility Electrification is reaching all corners of manufacturing lines — and

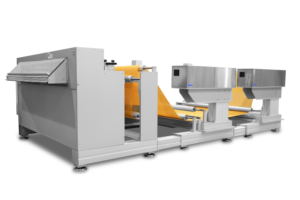

Modular Cutting Assemblies in Action

In our last blog post, we explored modular cutting assemblies that consist of “building blocks” that you can mix and match on new or existing converting lines. For low- and medium-volume converting operations, as well as production lines requiring frequent changeovers, this modular approach reduces time, effort and complexity compared to large, purpose-built machines that must be matched to a single production line.

Driving Flexibility and Cost Savings With Modular Cutting Assemblies

Traditionally, cutting operations on converting lines are tightly coupled with a single large-scale manufacturing process — an approach that involves costly, purpose-built machines designed for fast line speeds, around-the-clock operation and high-volume web speeds.