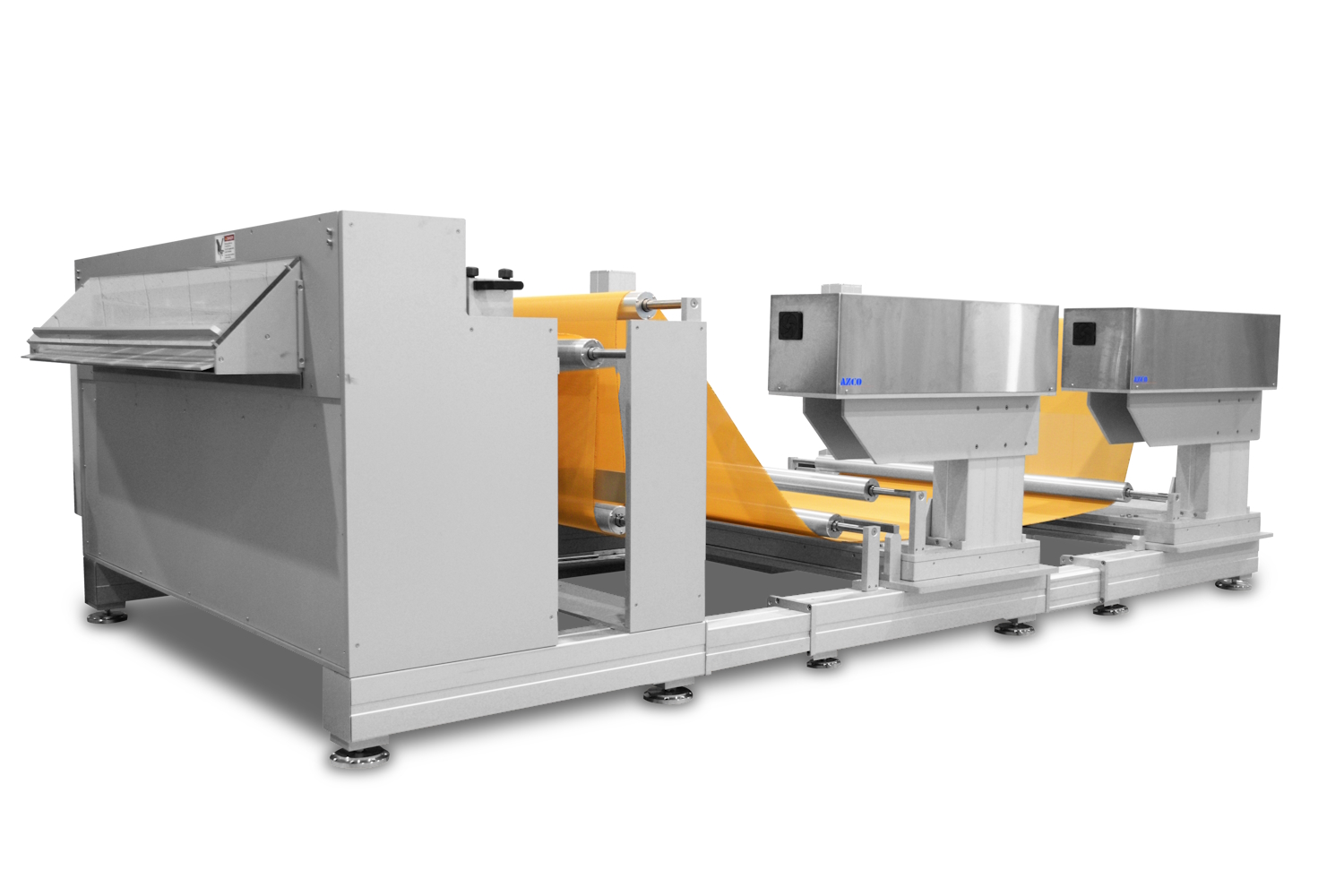

Exploring Our SUR SIZE™ Sheeter FGW 1650 for Unwinding, Slitting and Cutting

We’re spotlighting our SUR SIZE™ Sheeter FGW 1650, a highly versatile and customizable cutter that includes heavy-duty unwinds, slitter station and edge guides to precisely unwind, slit and cut various materials. These units can cut various flexible materials like films, foils, nonwovens, laminates and paper. They feature a rugged, clear anodized frame with stainless steel covers and include an air shaft supported by safety chucks for quick and easy roll changes — a design that maintains continuous operations and minimizes downtime.

Here’s an overview of how the SUR SIZE™ Sheeter FGW 1650 works.

Rolls of material are loaded onto the unwind station as safety chucks hold the air shaft and material in place. Next, the material passes under a set of rollers and through an edge guide system. Along with a variable speed motor and control panel, the unwind station can include an edge guide system to track and adjust the material to position the web.

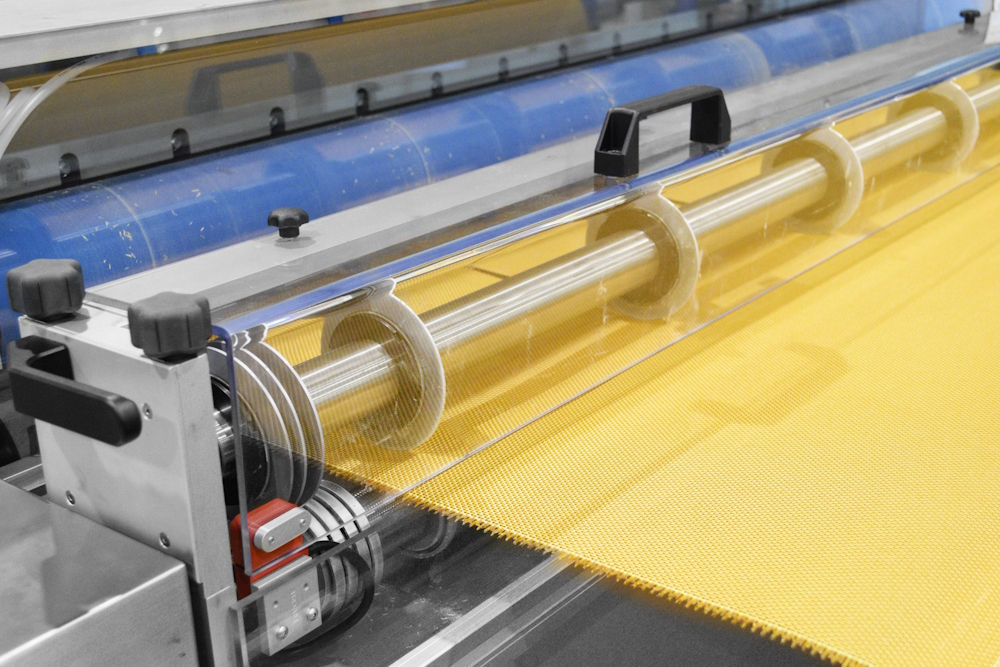

The unwind station also incorporates a dancer assembly that maintains constant web tension, ensuring materials are fed into the slitter station at consistent tension levels. This feature is crucial for achieving clean, precise cuts. Once the material is pulled into the slitter station, rotary shear blades precisely and cleanly cut it into strips.

Next, ground urethane rollers pull the material into the cut-to-length station, where a hardened tool steel blade cuts the slit material. Finally, cut pieces exit via a safety enclosed chute. An optional conveyor or stacking system is available.

The SUR SIZE™ Sheeter FGW 1650 also includes a no-product sensor that will shut the unit down if it doesn’t sense material entering the slitting station or knife assembly. It also has a color touchscreen, allowing operators to easily set up and monitor the cutting process.

A Flexible Unit To Meet Your Needs

Thanks to our modular, “building block” approach, cutting assemblies like the FGW 1650 support additional features to meet your specific operational needs. For example, we can seamlessly integrate unwind and rewind stations, sensors, light towers, eye registration, punches, web-guiding systems, tray lifts, conveyors and more.

Additional technical specifications of the FGW 1650 include:

- Maximum cut width: 1,650 mm.

- Servo motor drive system.

- Tolerance: +/- 0.38 mm or +/- 0.1% — whichever is larger.

- Power requirements: 110 V AC or 220 V AC.

- Compressed air requirements: 30 to 90 psi.