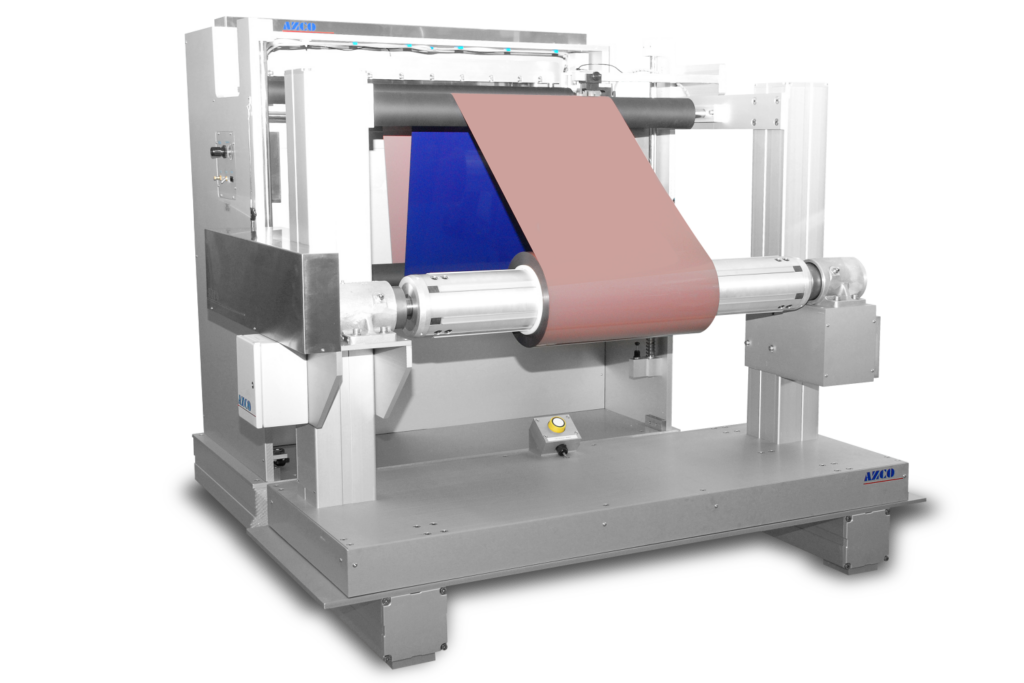

SUR-SIZE™ Sheeters: Advanced Cutting Technology for Precision Material Processing

In today’s fast-paced manufacturing world, efficiency and precision are essential. Our SUR-SIZE™ sheeters — specifically the FGW-1000 and FGW-1650 — are increasing production across multiple industries by delivering precision cutting, seamless operation, unmatched versatility and increased production. You can even add automatic stackers to reduce handling time.

Why Choose the FGW-1000/1650 Sheeters?

Designed for processing flexible materials with superior accuracy, the FGW-1000/1650 offer a highly customizable solution for continuous manufacturing. Its key features include:

- Quick roll changes. Equipped with an air shaft supported by safety chucks, these sheeters streamline material changes, reducing downtime and keeping production on track.

- Precision cutting technology. The machine’s precision-ground urethane rollers, powered by a brushless servo motor, ensure clean, consistent cuts with minimal maintenance.

- User-friendly controls. Operators can easily adjust settings using an intuitive touchscreen interface, simplifying setup and operation.

- Optimal web tension control. The motorized unwind and dancer assembly maintain perfect tension, allowing material to move smoothly over ball-bearing idle rollers, ensuring high-quality, precise cuts.

- Versatile material processing. With a maximum cut width of 1,650 mm (65 in.) and a material width of up to 1,600 mm (63 in.), the FGW-1000/1650 are ideal for cutting:

- Films and foils

- Nonwoven fabrics

- Paper and laminations

- Rubber and industrial materials

- High-performance materials

Enhance Your Production Efficiency with SUR-SIZE™ Sheeters

If you’re looking to upgrade your equipment or expand your production capabilities, the FGW-1000/1650 sheeters are engineered to boost efficiency, precision and ease of operation.

Contact us today to learn how SUR-SIZE™ sheeters can optimize your manufacturing process and reduce your cost.