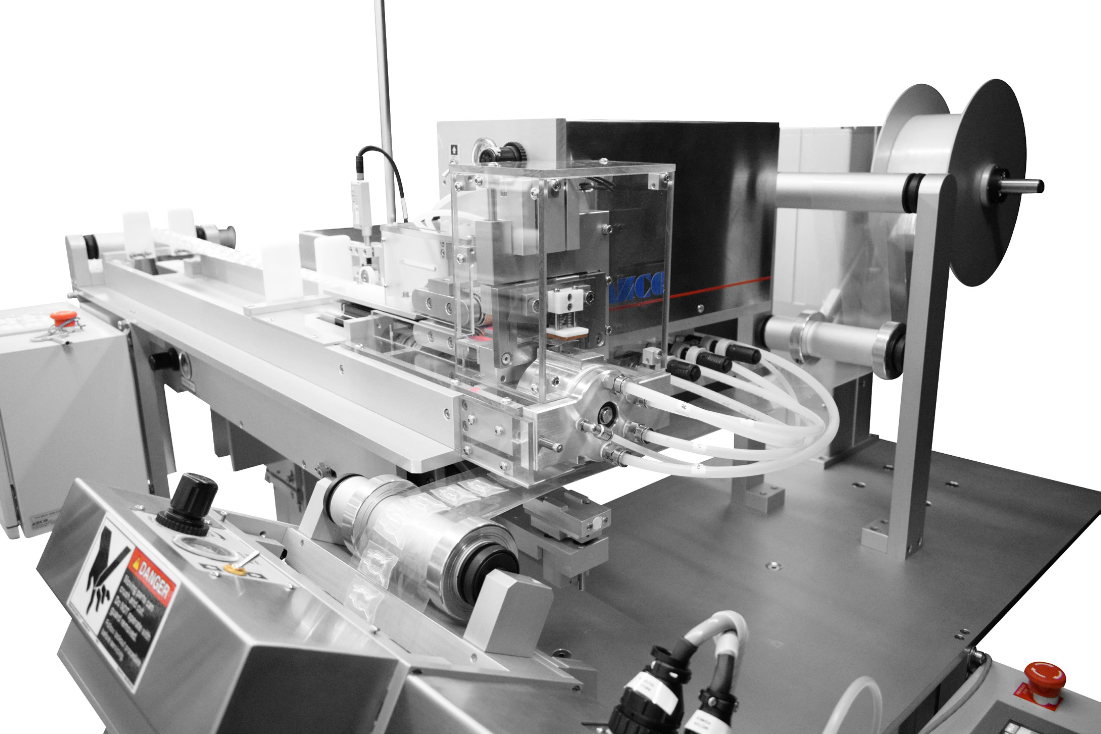

Engineered for seamless integration with existing converting equipment, the AZCO VPS valve placing machine offers customizable interface options to fit your setup.

KEY FEATURES

- Automatic Material Feed & Precise Valve Placement: Materials are loaded onto the unwind, and the valve is automatically indexed and positioned precisely.

- High-Accuracy Registration: Equipped with advanced registration systems to ensure accurate positioning before cutting, with verification that each valve is active.

- Heat Sealing Capability: Once cut, the valve is placed on an indexing system and securely heat-sealed onto the pouch machine.

- Plug-and-Play Installation: Self-contained system that requires only a 220V power connection and pressurized air for operation.

COMPATIBILITY AND INTEGRATION

- Flexible Operation: The VPS machine operates as a “slave” to your existing process, synchronizing positioning based on your printed web.

- One-Shot Signal Interface: For non-registered materials, the system simply requires a one-shot signal for positioning.

This versatile solution brings precision and automation to valve placement, enhancing production efficiency with minimal setup.

BENEFITS

- Quick installation and interface with most machines

- Accurate valve positioning on the web

- Fully automated

- Self-contained easy to move to, relocate

- Compact cantilever design for complete access across the web

SPECIFICATIONS

- Cycle rate: 80 cpm (based on seal time)

- Requires 220 VAC, compressed air

- Interface: eye registration of the web (included) or one-shot signal needed for non-printed material