One of our latest machines has arrived just in time for PACK EXPO 2024. This valve applicator applies the ValvPak® valve technology to pouches, offering a more sustainable and efficient liquid packaging solution than traditional rigid fitments. It also demonstrates our ability to design modular, plug-and-play machines that can handle unique applications in the food packaging space.

About ValvPak®

ValvPak is a patented, self-contained and flexible valve that sits inside the pouch and controls the liquid dispensing. It can accommodate a wide range of liquid viscosities — from water to toothpaste — and won’t spill, even if the pouch is placed on its side or held upside down.

Here’s how ValvPak works: when the pouch is squeezed, the valve opens. Once pressure is released, the valve automatically closes, stopping the flow of liquid. It’s as simple as that.

Compared to traditional liquid packaging solutions that rely on fitments or straws, ValvPak is a big step forward in sustainability. By reducing the need for rigid plastic fitments and overwraps, this flexible valve technology reduces materials and cost. It is also a good replacement for straws because the valve, which sits inside the pouch, is protected from outside contaminants. Once users remove the top seal, they can place the valve in their mouths and simply squeeze the contents out.

ValvPak also retains product freshness and cuts down on waste. Even after the top seal has been removed for initial use, ValvPak helps to prevent the product inside the pouch from coming into contact with the air, keeping it as fresh and stable as it was before the pouch was opened.

AZCO Machine Applies ValvPak With Ease

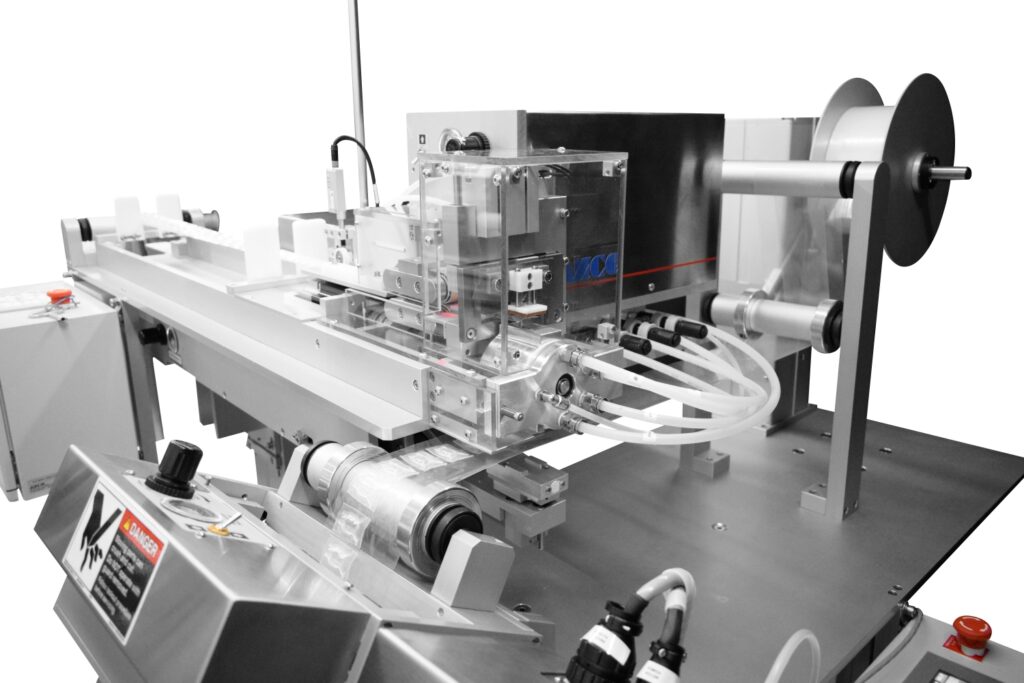

We designed a modular, free-standing machine that easily integrates into existing machinery to apply ValvPak to pouches, enabling more manufacturers to take advantage of this innovative valve technology. This valve applicator machine consists of unwind, feeder, indexing and heat seal stations — all of which are mounted on an easy-to-install equipment frame.

To operate the machine, simply plug in air and power — no other integration required. Using an optical sensor, the machine picks up the mark on the film, then registers, indexes and heat seals the valve to the film at typical pouch machine speeds of over 80 units per minute. The pouches come off the machine ready to be filled.

See the Machine in Action at PACK EXPO 2024

To see the valve applicator in action, be sure to visit us at Booth N-5835 (North Building) at PACK EXPO. We’ll have this machine on-hand, along with some of our other latest innovations in feeding and cutting. Learn more at: packexpointernational.com.

To learn more about ValvPak technology, visit: valvpak.com.